Product Category

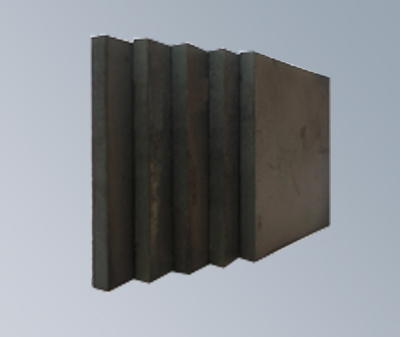

Hot-pressed Sintered Boron Carbide

| Hot-pressed sintered boron carbide method is production process that simultaneously heats and pressurizes during sintering process to form densification, and obtains boron carbide ceramic material that has the best performance comparing with other sintering methods. However, due to the constraints of hot-pressing process, the obtained products have restriction in size, shape and production quantity. This process is only |

suitable for small batch production of high-performed and simple-shaped products. The cost is relatively higher and the production cycle is slightly longer. Performance characteristics: high hardness (> HV3300), high strength, good wear resistance, and small density. Suitable for: hard panels in advanced bulletproof armor, blast nozzles, water cutting nozzles, etc. |

Ceramic Panel for Bulletproof Armor

|

Ceramic Materials

Contact Us

- TEL:0451-84368085

- 0451-84368082

- 0451-82296796

- Fax:0451-84368083

- Addr:No.18 Donghu Street, Daoli District, Harbin

- Zip code:150090

Home Page | About Us | Product Display | Product Application | Ceramic Materials | Technical Support | Declaration of Responsibility | Contact Us

All Rights Reserved:Harbin Xinhui Special Ceramics Co., Ltd. Technical Support:Hong Xin Network | Black ICP 11003677 -1

All Rights Reserved:Harbin Xinhui Special Ceramics Co., Ltd. Technical Support:Hong Xin Network | Black ICP 11003677 -1